Introduction

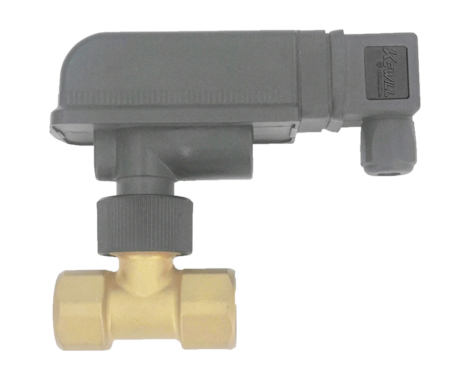

Principle & Structure

The flow switch consists of a vane system (1) at its other end connected to a permanent magnet (2), on top of this magnet is a reed contact (3), this part is placed on the outside of the liquid. There is also a magnet (4) which has the same pole as the previous magnet and generates a certain force to reset the switch to the no-flow position.

When the liquid rushes to the baffle, the baffle swings, changing the relative position of the magnet (2) and the reed contactor (3), activating the contactor, and once the liquid flow is interrupted, the blade returns to the starting position, activating again contactor. The mutual repulsion of the two magnets eliminates the force required to reset the magnets. Use magnetic force instead of normal spring components to achieve stable and durable use and no sensitivity to pressure peaks.

Features

● Low pressure drop switch point measurable

● Instant response pressure 250bar

● On and off depends only on flow, not on temperature or pressure

● The reed contactor as the induction element is composed of two magnetic pieces, which are placed in a glass tube filled with inert gas. This method eliminates the loss caused by the burning of the contact.

● The switch point can be measured

● Pressure 250bar

optional features

special set point

LED inside the plug to show flow

Pressure resistance 250bar optional

Reed contactors with high switching performance