Introduction

principle

The metering box, a pair of oval gears installed in the metering box, and the upper and lower cover plates form a sealed crescent-shaped cavity (due to the rotation of the gears, so it is not absolutely sealed) as the calculation unit of primary displacement. When the liquid to be measured enters the flowmeter through the pipeline, the pressure difference generated at the inlet and outlet pushes a pair of gears to rotate continuously, and continuously transports the liquid measured by the lunar cavity to the outlet. The product of four times the secondary displacement is the total amount of liquid flow to be measured.

structure

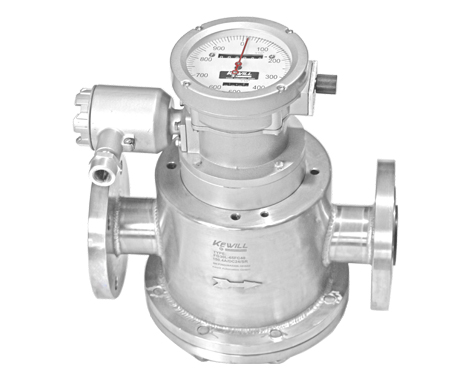

The oval gear flowmeter consists of a flow transmitter and a counting mechanism. A radiator is installed between the transmitter and the counting mechanism to form a high temperature flowmeter. The transmitter consists of a measuring chamber equipped with a pair of oval gear rotors and a sealed coupling, and the counting mechanism includes a deceleration mechanism, an adjustment mechanism, a counter, and a transmitter.

application

Suitable for asphalt, lubricating oil, vegetable oil, diesel oil, petroleum, residual oil, kerosene, motor oil, gasoline, heavy oil, fuel oil, heat transfer oil, crude oil, light oil, insulating oil, hydraulic oil, etc.