Introduction

principle

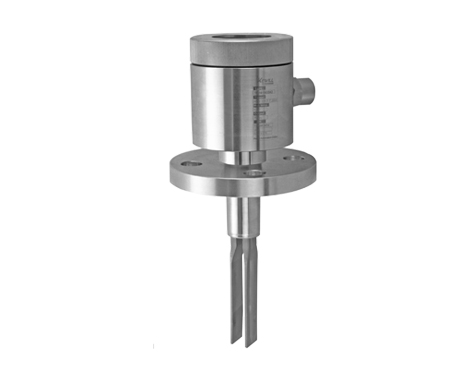

The working principle of the tuning fork level switch is that through a pair of pressures installed on the tuning fork base, the transistor makes the tuning fork vibrate at a certain resonance frequency. When the measured material covers the tuning fork, the vibration is slowed down. The transformed vibration frequency is automatically sensed, and the signal is processed to adjust the relay to achieve the purpose of indication or control.

Features

Strong adaptability - the different electrical parameters and density of the tested material will not affect the measurement. Harsh conditions such as scaling, agitation, turbulence, air bubbles, vibration, medium viscosity, high temperature, and high pressure have no effect on inspection.

Maintenance-free – Since the inspection process of the tuning fork limit switch is completed by the electronic circuit, there are no moving parts, so once installed and put into operation, no maintenance is required.

No need to adjust – because the inspection of the tuning fork limit switch is not affected by the dielectric parameters and density of the test medium, no on-site adjustment is required no matter what kind of liquid is measured.

Function

It is suitable for fixed-point alarm or control of solid material level in various silos and liquid level in various containers.

Solid Materials: Free-flowing, medium-density solid powders or granules.

Such as: fly ash, cement, sand, stone powder, plastic particles, salt and sugar, etc.

Liquid medium: explosive and non-explosive dangerous liquid, corrosive liquid (acid, alkali) high viscosity liquid.

Such as: tap water, acid-base solution, mineral water pulp, dyes, oils, milk, alcohol, beverages, etc.

application

Paper making, brewing, cement, chemical industry, dairy products, edible oil, food and beverage

Sugar, fertilizer, glass, textile, semiconductor, water and sewage, pharmaceutical manufacturing

Coal mines, smelting, paint workers, oil and gas, metal packaging.